I bought the plans for this jig from Luthiers Cool Tools. I chose to build this jig because of its small footprint and robust design and construction. The plans are clear, concise and understandable. A bill of materials is provided as well as sources for the hardware and components. I bought most of the hardware from local sources. Bearings and UHMW polypropylene were purchased from McMaster Carr and the router bit was purchased from Rockler. Included in the plans are radius templates for inserts that will produce 12”, 14”, 16”, 18”, 20”, 22”, 24” radii. The jig is capable of producing compound radii on fretboards. It is constructed from ?” Baltic birch ply for the frame and hardwood for carrier board, guide blocks and bearing mounts. The router rides in a track bordered by aluminum angle stock.

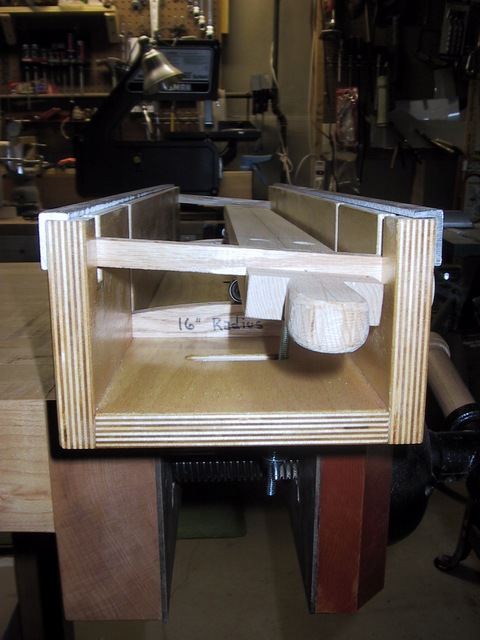

This shows the jig mounted in a bench vise ready for action.

I made a simple square router base lined with UHDMW polypropylene to allow the router to slide securely and freely within the track. I found that the round base was too easily tipped and bound as it traveled. The router bit is a 3/4" core box bit from Rockler.

This shows the FB half done. It took about 20 passes to get this far. I indexed the carrier board about 1/16" for each pass.

This is the completed board. Just a light sanding with 100 grit was all that was needed to smooth out the machine marks. I used the 1/4" setup block to adjust the bit height before starting the operation.

The jig was quite simple to build. It's very important to dimension the carrier board perfectly. It must be straight and dead flat. I chose to use 7/8" hard maple for this and had my Amish buddy joint and thickness sand it until it was just right. The results were that the first board was dimensionally uniform on from end to end.

I tested this out on a maple board initially before risking a BRW FB. So with a sample size of 1 so far, I'm happy with the results.

Thanks for looking...now fire away with questions, suggestions, comments...but please, no tomatoes!